The Of Roar Solutions

The Of Roar Solutions

Blog Article

Examine This Report about Roar Solutions

Table of ContentsRoar Solutions Things To Know Before You BuyThe 5-Second Trick For Roar SolutionsThe Ultimate Guide To Roar SolutionsWhat Does Roar Solutions Do?

The tools register is a thorough data source of tools records that consists of a minimum set of areas to determine each item's area, technological specifications, Ex lover classification, age, and ecological information. This details is important for tracking and taking care of the equipment properly within hazardous areas. In contrast, for regular or RBI tasting examinations, the quality will be a combination of In-depth and Close assessments. The proportion of In-depth to Close assessments will certainly be established by the Equipment Danger, which is assessed based upon ignition danger (the possibility of a source of ignition versus the likelihood of a flammable environment )and the hazardous area category( Zone 0, 1, or 2). This variation will additionally influence the resourcing demands for job preparation. As soon as Lots are defined, you can establish tasting plans based upon the sample dimension of each Whole lot, which refers to the number of random devices things to be examined. To establish the needed sample size, two facets need to be evaluated: the dimension of the Lot and the category of inspection, which shows the degree of effort that should be applied( lowered, normal, or enhanced )to the assessment of the Whole lot. By integrating the classification of examination with the Lot size, you can after that establish the suitable denial criteria for an example, indicating the allowable number of damaged products located within that sample. For even more details on this process, please refer to the Energy Institute Guidelines. The IEC 60079 typical suggests that the optimum interval between inspections must not surpass 3 years. EEHA evaluations will certainly also be carried out outside of RBI campaigns as part of set up maintenance and equipment overhauls or fixings. These examinations can be credited towards the RBI sample sizes within the impacted Great deals. EEHA inspections are conducted to determine mistakes in electrical equipment. A weighted racking up system is important, as a single item of devices may have numerous faults, each with varying levels of ignition risk. If the combined rating of both evaluations is less than two times the mistake rating, the Great deal is considered appropriate. If the Lot is still taken into consideration undesirable, it must undertake a full assessment or justification, which may trigger more stringent evaluation protocols. Accepted Whole lot: The reasons for any kind of faults are identified. If a typical failure mode is found, added devices may need maintenance. Mistakes are categorized by severity( Security, Stability, Housekeeping ), ensuring that immediate issues are examined and resolved without delay to mitigate any type of influence on security or operations. The EEHA database must track and record the lifecycle of mistakes together with the rehabilitative activities taken. Carrying out a durable Risk-Based Evaluation( RBI )approach is crucial for guaranteeing compliance and security in taking care of Electrical Tools in Hazardous Areas( EEHA). Automated Fault Scoring and Lifecycle Monitoring: Easily manage faults and track their lifecycle to improve assessment precision. The intro of this support for risk-based evaluation even more strengthens Inspectivity's setting as a best-in-class service for regulatory compliance, in addition to for any kind of asset-centric assessment usage situation. If you are interested in finding out more, we welcome you to ask for a presentation and find exactly how our option can change your EEHA monitoring processes.

With over 10 years of consolidated Ex lover experience (IECEx/ATEX, EEHA), Saipex started to advertise the significance of competence of all personnel associated with the Hazardous Location field in 2019. In 2021, our collaboration with IndEx and Tech Skill International (TSI) marked a milestone in the Saipex road to proceed Ex lover renovation.

The smart Trick of Roar Solutions That Nobody is Discussing

In terms of eruptive risk, a harmful location is a setting in which an explosive atmosphere exists (or might be expected to be existing) in amounts that require special safety measures for the construction, installation and usage of equipment. In this short article we explore the challenges encountered in the office, the threat control steps, and the called for expertises to function securely.

(https://moz.com/community/q/user/roarsolutions1)

These substances can, in particular conditions, create eruptive ambiences and these can have significant and heartbreaking repercussions. Most of us are familiar with the fire triangle eliminate any type of one of the 3 aspects and the fire can not occur, but what does this mean in the context of harmful locations?

This is after that verified via assessment and testing and is protected throughout the life of the setup by utilizing the right upkeep strategies, supplemented by periodic inspection. When all these actions are taken, they ought to also be documented. The confirmation file consists of details such as the unsafe area category drawing, producers' documents, devices accreditation, style drawings and computations, examination documents, and records of an individual's proficiency and proceeding specialist advancement (CPD), such as via ECA's eCOMS software.

See This Report about Roar Solutions

It is essential that trainees recognize and have an extensive knowledge as to what specifically constitutes a hazardous location. The trainee should additionally recognize why training is essential prior to trying to tackle work or specifying devices right into a harmful area. These locations are likewise recognized as identified areas and are specified as areas which have a high probability of a surge as a result of the feasible existence of flammable gases, vapors, dusts etc.

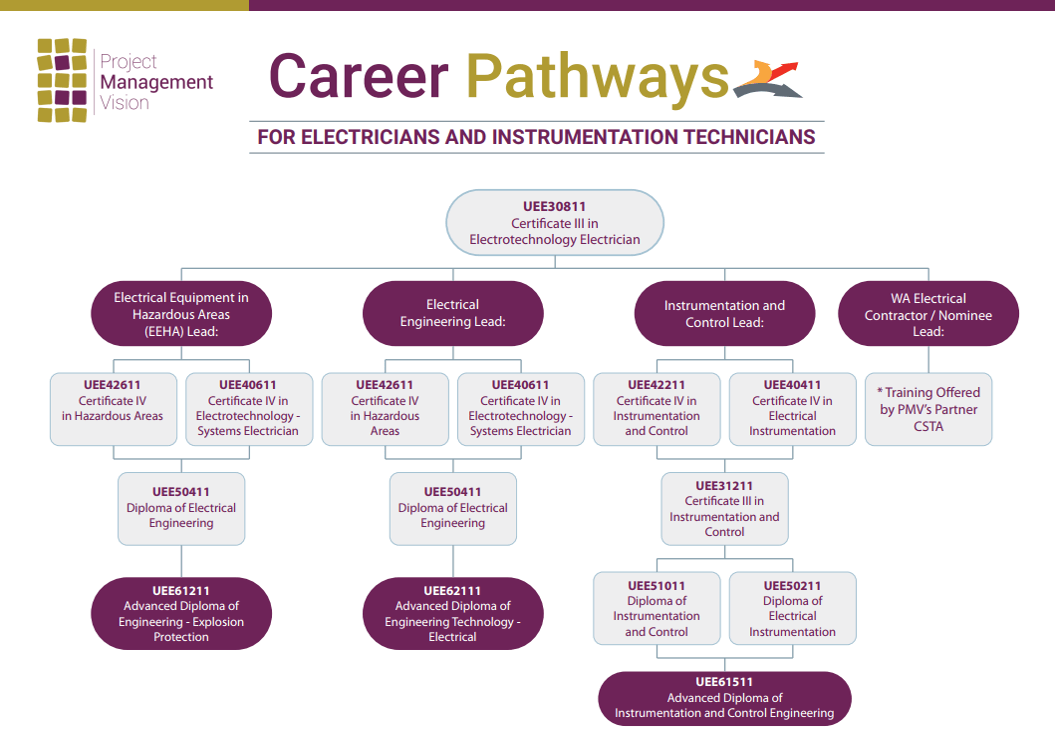

Industries which contain dangerous areas are currently demanding that electrical employees that are specifying or functioning in these locations must have a harmful location certification that considers them qualified. Jobs in these industries are really rewarding so you require to be prepared. To meet this demand for the market, country wide identified training in Certificate IV in Harmful area her comment is here Electrical and EEHA training on the advancement of knowledgeable professionals.

More About Roar Solutions

Technology Skills Australia is a Registered Training Company providing you with one of the most budget friendly and quickest method acquiring your credentials - Roar Training Solutions. Our teachers are market qualified and have a number of years of procedure experience. Our programs have assisted thousands of individuals from corporate managers to everyday staff members in getting a strong hang on this not so complicated yet high threat training

The training also includes determining the harmful locations, sources of surge and the residential or commercial properties of unsafe products in addition to the obligations and functions of all celebrations, policies, systems, requirements and practice codes linked to hazardous locations. We offer instrumentation and unsafe area services that are in compliance to newest AS/NZS and international market standards.

Report this page